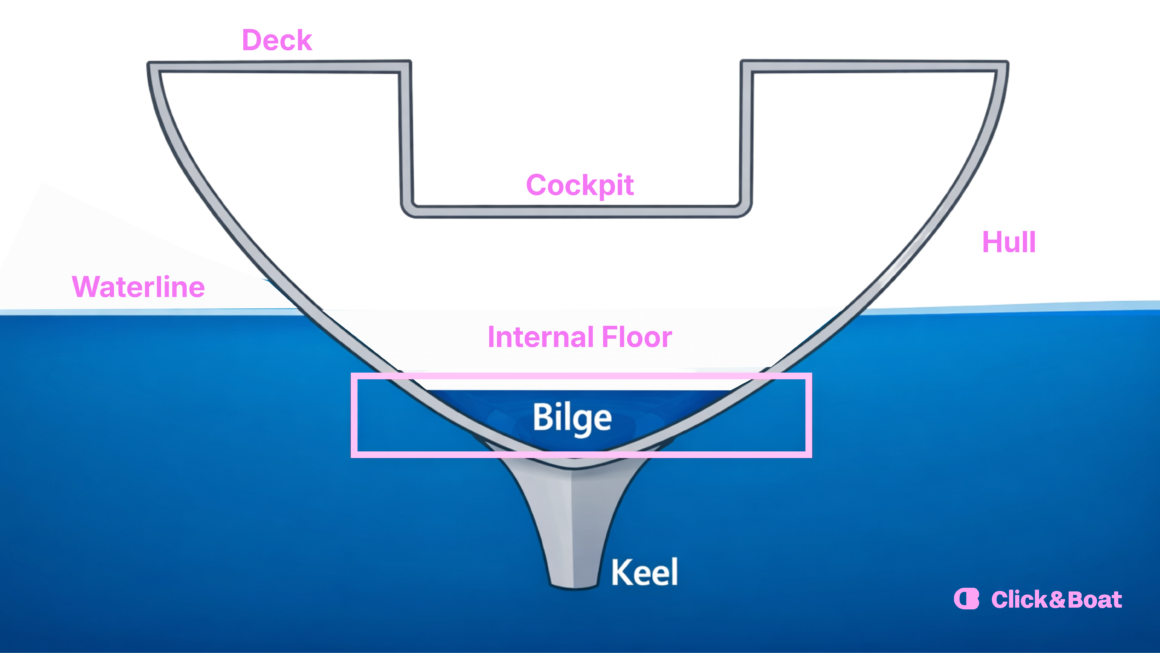

On any boat, the bilge is the lowest inner part of the hull, where the bottom curves up into the sides along the keel. It sits below the cabin floorboards and engine beds and acts as a catch-all for any water, fuel drips or spills that find their way inside the boat. Because gravity pulls liquids to the lowest point, everything eventually ends up in the boat bilge.

In a well-maintained vessel, this area should stay as clean and dry as possible, but a little “nuisance water” is almost inevitable. That is why every skipper should understand how the bilge works, what type of bilge pump they have on board and how to look after it.

How does a bilge work?

Structurally, the bilge runs along the inside of the hull on either side of the keel. Frames, stringers and bulkheads often have limber holes that let water flow aft into a sump where it can be pumped out.

Water reaches the bilge from many everyday sources: rain coming through hatches, spray over the bow, small leaks around shaft seals, or water from washing down the deck. Instead of sloshing around underfoot, this water drains down to the bilge.

From there, one or more bilge pumps move it overboard through dedicated discharge hoses. On many boats a float switch or built-in sensor starts the pump automatically when the water level rises, then stops it again once the bilge is nearly dry. The system is simple, but it is a key part of your safety gear.

Why do you need a bilge pump?

A bilge pump keeps the boat dry, protects equipment and, in extreme cases, can buy you time in an emergency. Even a small leak or a dripping stuffing box will slowly raise the water level in the bilge. If that water is not removed, it can:

- Soak wiring, corrode fittings and damage batteries or electronics

- Lead to mold, bad smells and slippery surfaces

- Affect trim and stability if a lot of water collects low in the hull

Most of the time, a bilge pump simply handles everyday accumulations of “nuisance water”. In a flooding situation, it will not replace a proper damage-control response, but it can work alongside manual pumps and buckets to reduce the inflow. For this reason many safety guides recommend at least one automatic electric pump plus a manual backup.

Understanding what the bilge on a boat is helps you see why keeping this space dry is so important for safety and comfort.

Where are bilge pumps located?

Bilge pumps should sit where water naturally collects: as low and as central as possible along the keel, but still accessible for inspection and service. On many sailboats you will find:

- Main electric pump in the deepest part of the cabin bilge

- Secondary pump further aft, often in the engine bay

- Manual pump with its suction hose reaching the same low point

Larger yachts and powerboats may have separate pumps in forward, midships and aft bilge compartments, each with its own discharge hose and check valve.

Whatever the layout, the pump should be securely mounted, wired above the normal waterline of the bilge, and connected to a strainer that keeps debris out of the mechanism.

Types of bilge pumps

Several types of bilge pumps are used on recreational boats. Each has different strengths, so many vessels use more than one style.

Centrifugal pump

Centrifugal bilge pumps are the most common electric models. A rotor spins and throws water out through the drain pipe. They move a lot of water for their small size, but they are not self-priming, so they must be installed very low in the bilge and do not remove the last few inches of water.

Diaphragm pump

Diaphragm bilge pumps are positive displacement pumps that use a flexible membrane to draw in and push out water. They are self-priming and can be mounted higher in the boat, but usually have lower flow rates and are more sensitive to debris.

Piston pump

Piston bilge pumps move water by sliding a piston back and forth inside a chamber. They can pump the bilge almost dry and handle thicker liquids, but are more complex and expensive, so they are often used as heavy-duty or manual backup pumps.

Flexible impeller pump

Flexible impeller pumps use a rubber impeller with bending vanes to move water from inlet to outlet. They are self-priming and can handle a mix of air and water. So it makes them useful as emergency or high-lift pumps. The impeller must be checked often because running dry can quickly damage it.

Your bilge maintenance checklist

Good bilge pump maintenance is as important as carrying lifejackets. Add these tasks to your routine checklist:

- Inspect the bilge area: Remove trash, loose cable ties, rags and other debris that could clog the pump or strainer.

- Clean the strainer and pump housing: Sludge and hair can block the intake. Rinse with fresh water and a bilge-safe cleaner.

- Test the float switch or sensor. Lift the float by hand or trigger the sensor and confirm the pump starts and stops correctly.

- Check wiring and connections: Look for corroded terminals, chafed insulation or loose crimps. Ensure the pump has a dedicated fused circuit.

- Inspect hoses and outlets: Make sure discharge hoses are secured, free of kinks and not cracked. Confirm water flows freely out of the thru-hull fitting.

- Run a full function test. Add some fresh water to the bilge, then watch the system cycle automatically from start to finish.

- Keep the bilge as dry as possible. Fix small leaks, wipe up spills and avoid pumping oily water overboard, which can be illegal as well as harmful.

Regular checks before and after the season will make it less likely that your pump fails when you need it. Before a longer trip on a charter boat, ask the owner or skipper to show you where the bilge pumps, switches and hoses are located.

Conclusion: a small space with a big safety role

The bilge may be hidden deep in the hull, it plays a major role in your boat’s safety and comfort. Understanding what the boat bilge is, how water moves through it and which types of bilge pumps you have on board helps you make better decisions when fitting out or upgrading your system. Once you know what the bilge on a boat is and how your pumps work, it’s much easier to spot problems early

With a sensible layout, reliable pumps and simple bilge pump maintenance habits, you greatly reduce the risk of flooding, equipment damage and unpleasant surprises at sea. A quick look into the bilge before each trip, and a thorough inspection every few weeks, is one of the easiest safety habits any skipper can adopt.